Description

Media: combustible gases according G 260, gaseous, liquid, gelatinous, highly viscous, pasty, contaminated, aggressive, liquid fuels

Body Materials: brass, galvanized steel, nickel plated brass, nickel plated steel, without non-ferrous metals, stainless steel 1.4101

The materials refer to parts in contact with the media.

Seal Materials: NBR, PTFE, FPM, CR, EPDM, special seal materials

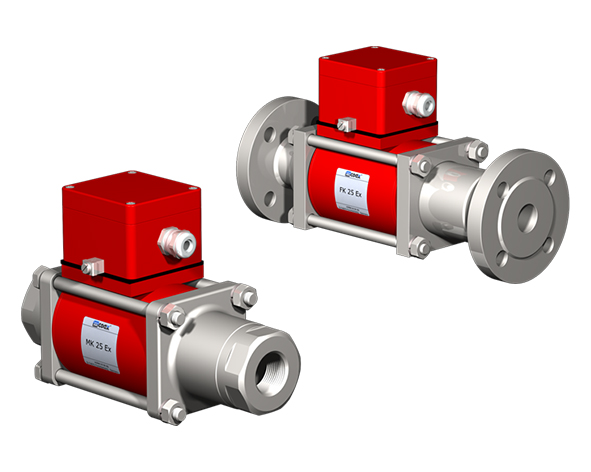

Certificates: PTB (Ex), TÜV, DVGW

Options: special threads, special flanges, function NO, damping, limit switches (NAMUR), manual override, approvals, special voltage, circuit amplifier, mounting

| co-ax type | orifice | Kv value | |

|

MK / FK 15 DVGW | 15 mm | 4,8 m³/h |

|

MK / FK 20 DVGW | 20 mm | 7,4 m³/h |

|

MK / FK 25 DVGW | 25 mm | 11,2 m³/h |

|

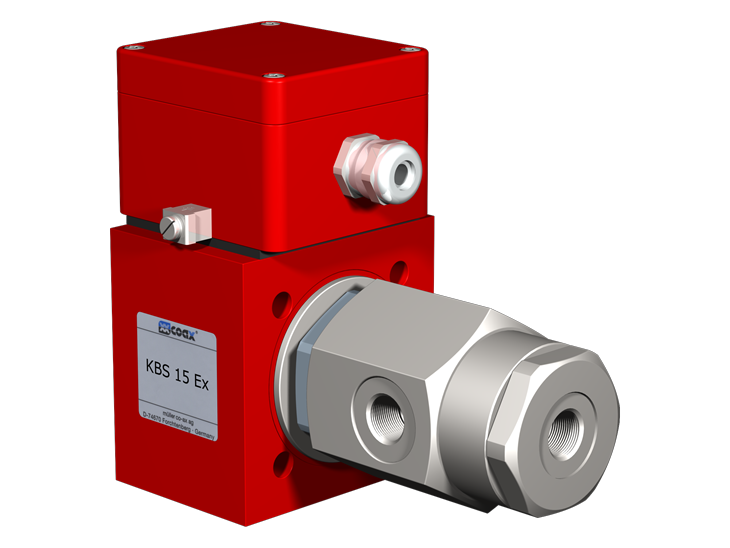

KBS 15 Ex | 1,5 – 3 mm | 0,066 – 0,312 m³/h |

|

KB 15 Ex | 2 – 8 mm | 0,102 – 1,44 m³/h |

|

MK 10 Ex | 10 mm | 2,5 m³/h |

|

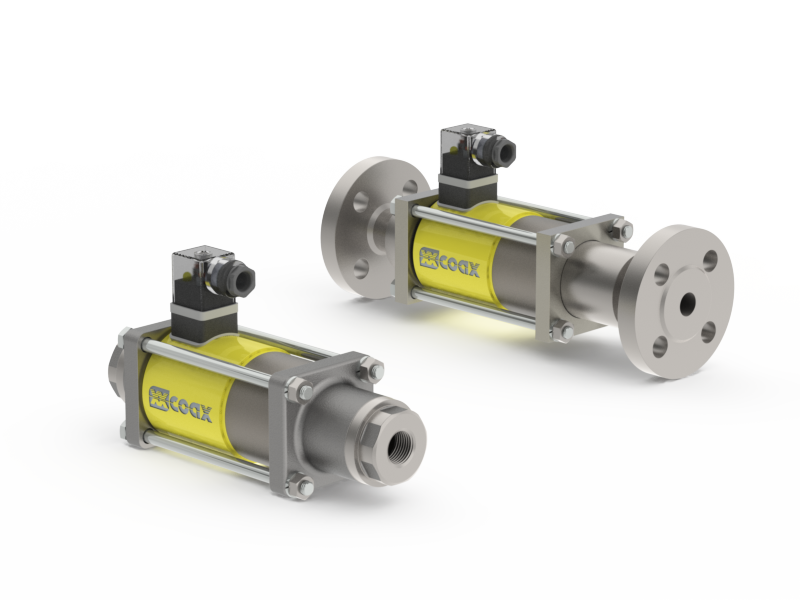

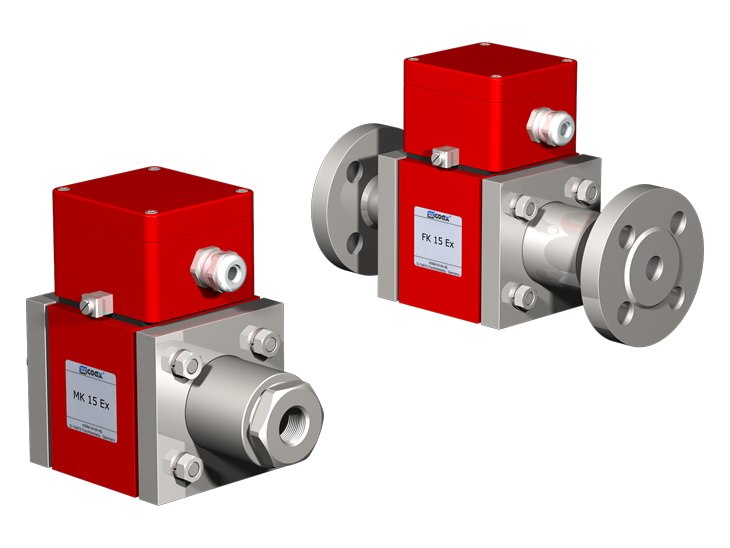

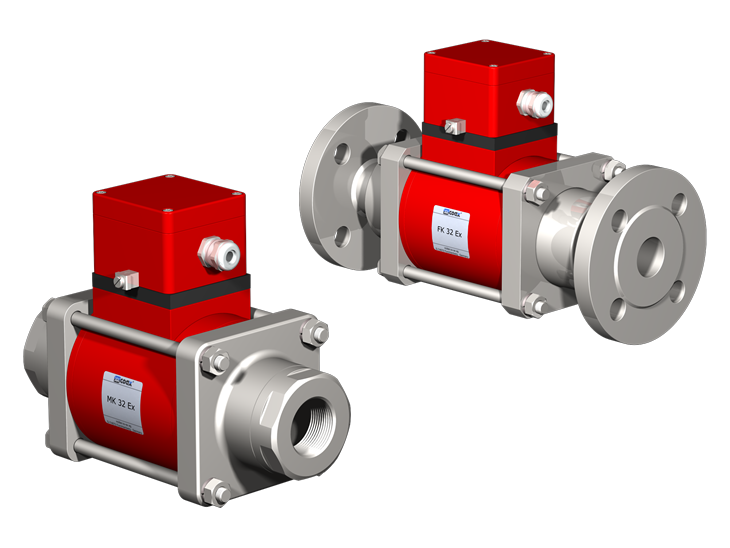

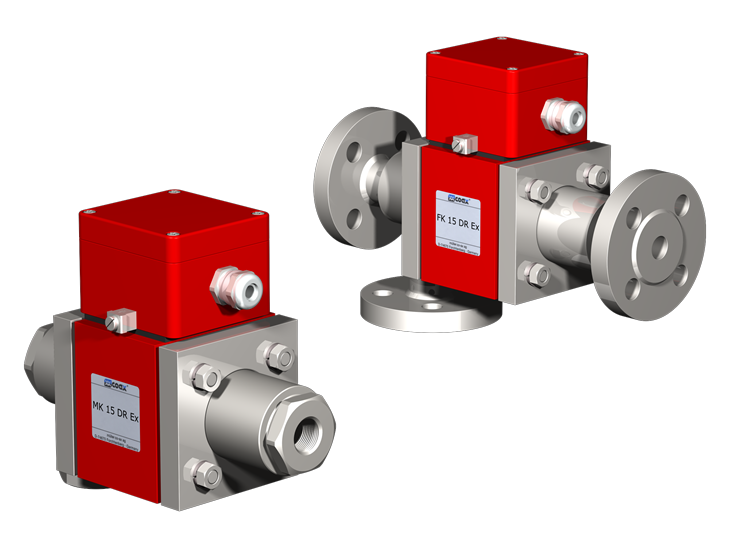

MK / FK 15 Ex | 15 mm | 4,8 m³/h |

|

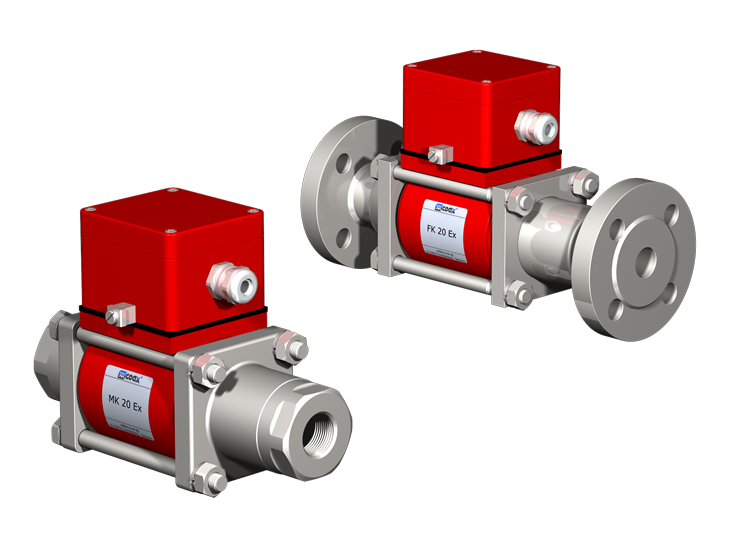

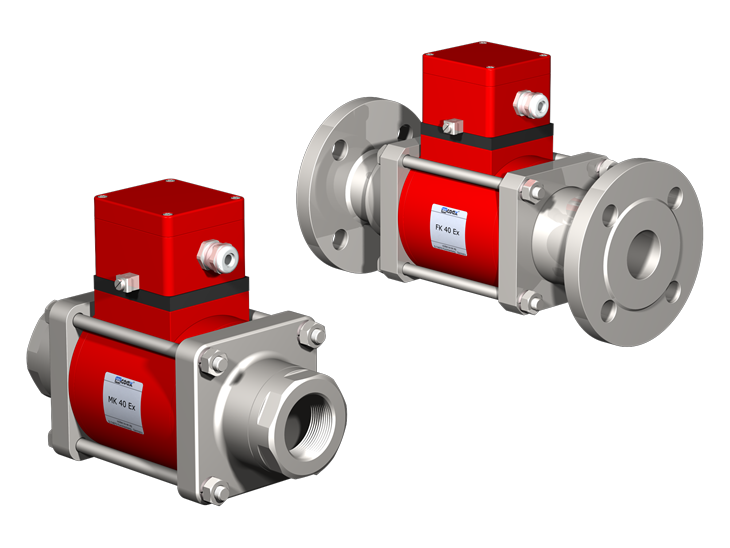

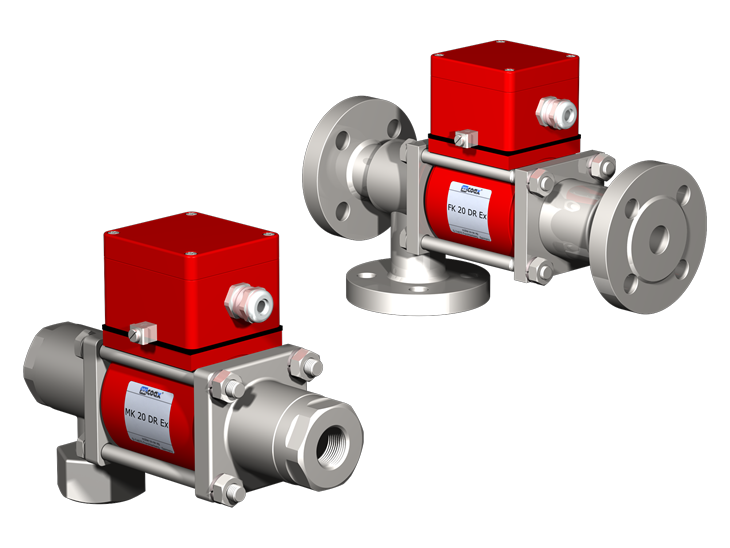

MK / FK 20 Ex | 20 mm | 7,4 m³/h |

|

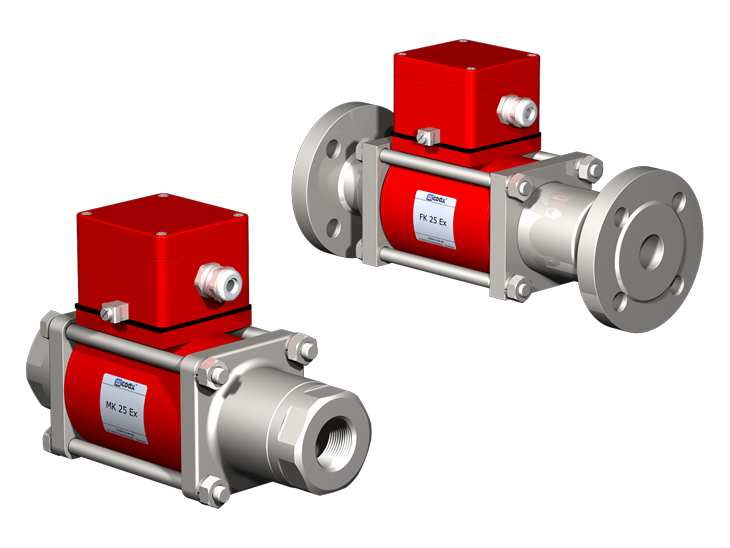

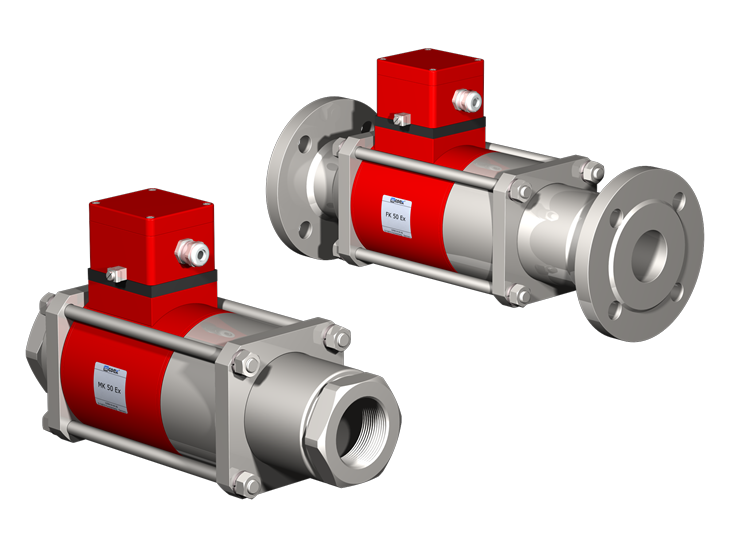

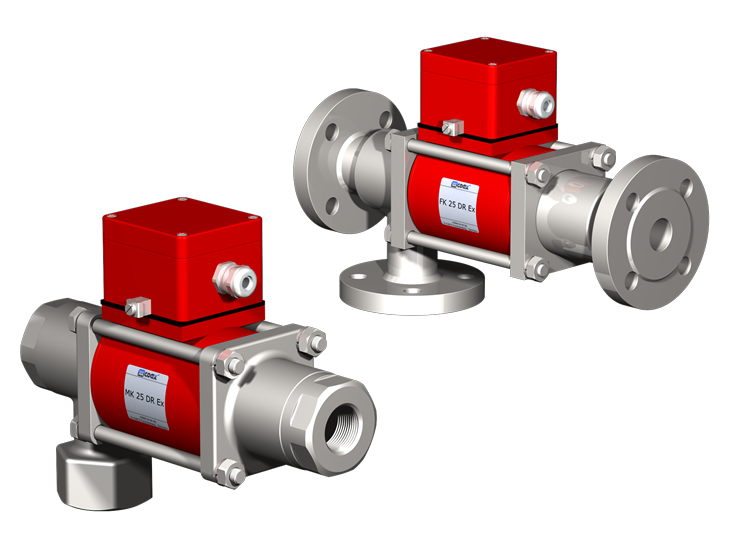

MK / FK 25 Ex | 25 mm | 11,2 m³/h |

|

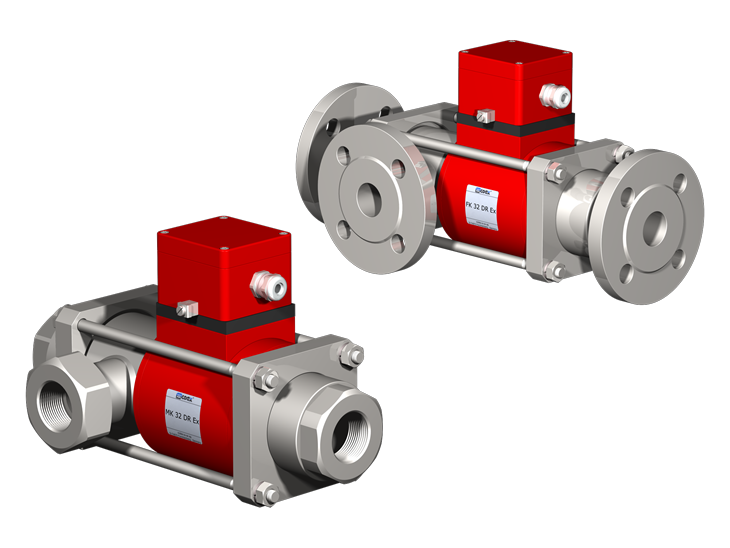

MK / FK 32 Ex | 32 mm | 14,1 m³/h |

|

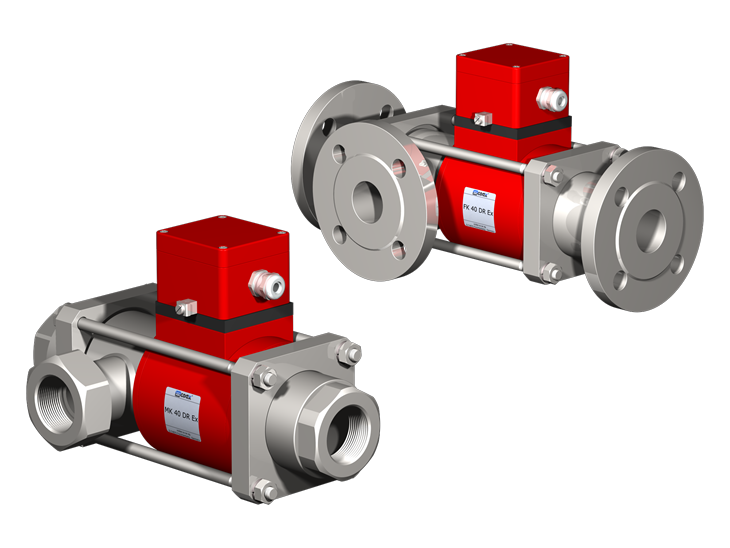

MK / FK 40 Ex | 40 mm | 18,4 m³/h |

|

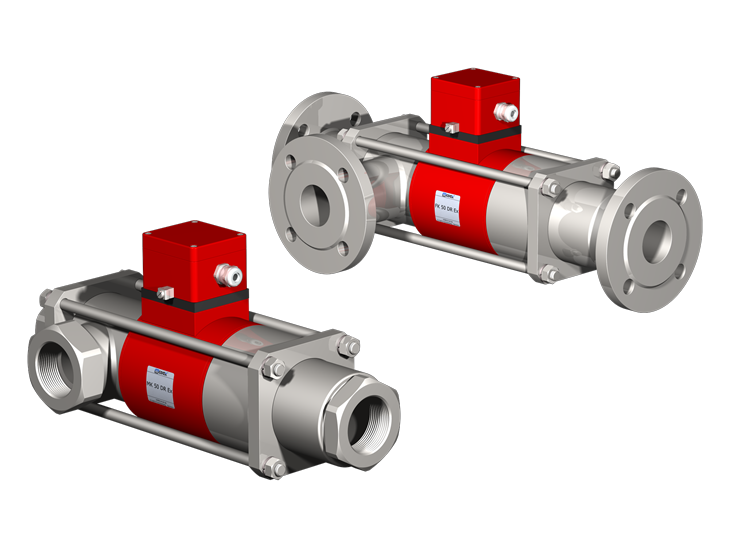

MK / FK 50 Ex | 50 mm | 28 m³/h |

|

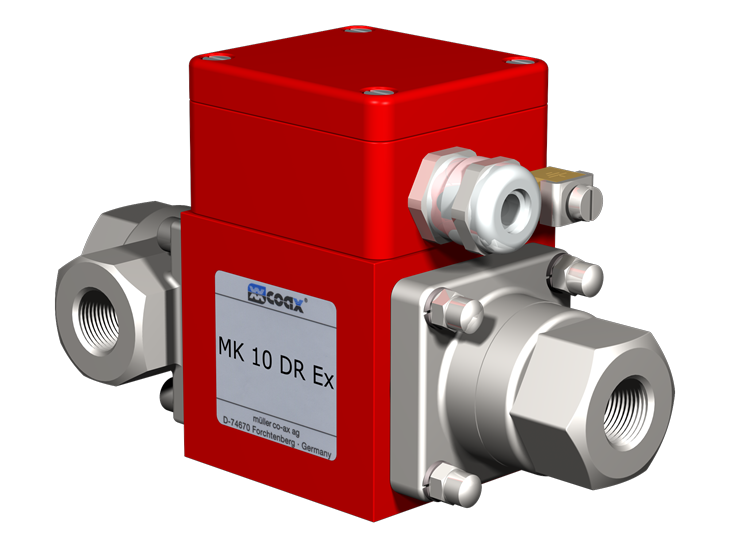

MK 10 DR Ex | 10 mm | 2,6 m³/h |

|

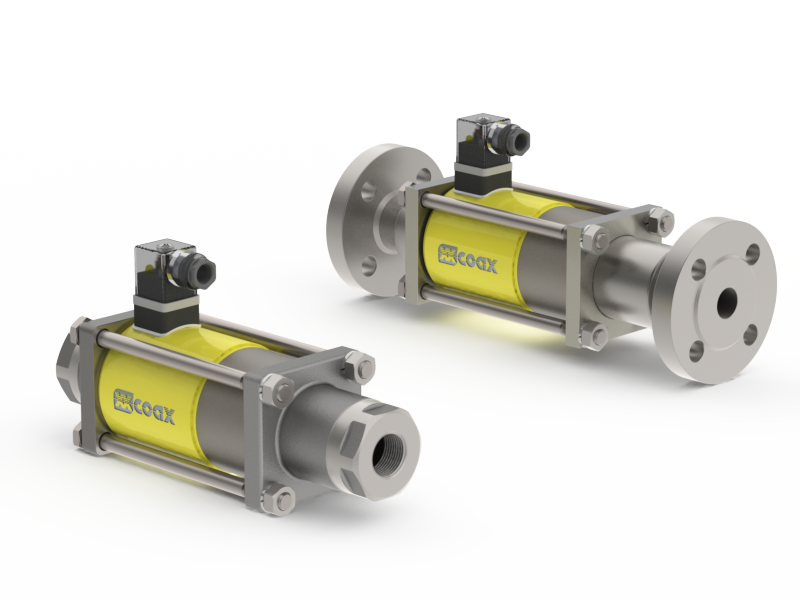

MK / FK 15 DR Ex | 15 mm | 4,3 m³/h |

|

MK / FK 20 DR Ex | 20 mm | 6,7 m³/h |

|

MK / FK 25 DR Ex | 25 mm | 11,2 m³/h |

|

MK / FK 32 DR Ex | 32 mm | 14,1 m³/h |

|

MK / FK 40 DR Ex | 40 mm | 18,4 m³/h |

|

MK / FK 50 DR Ex | 50 mm | 28,2 m³/h |

|

MK 10 TÜV | 10 mm | 2,5 m³/h |

|

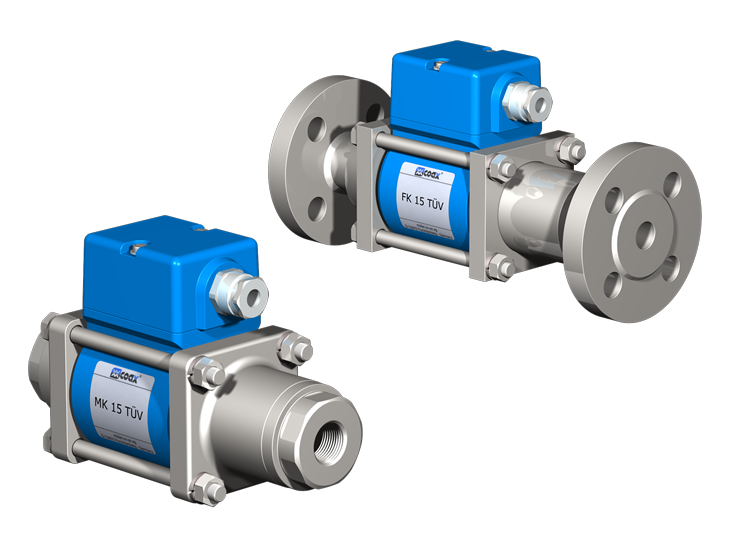

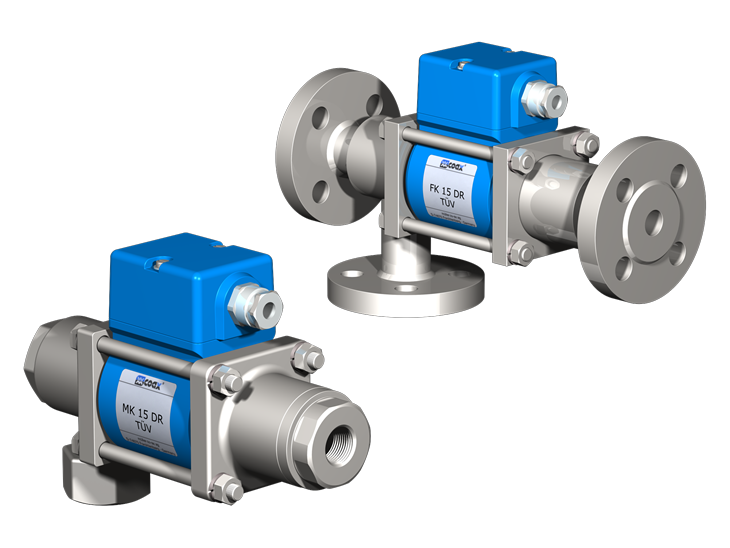

MK / FK 15 TÜV | 15 mm | 4,8 m³/h |

|

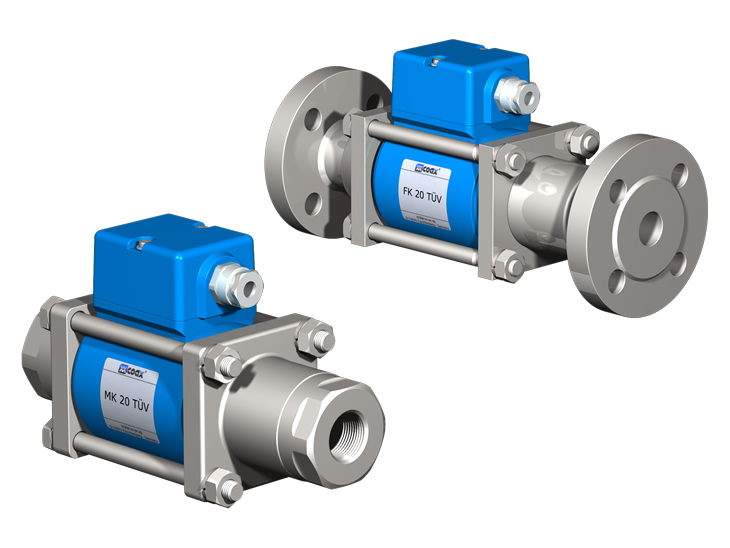

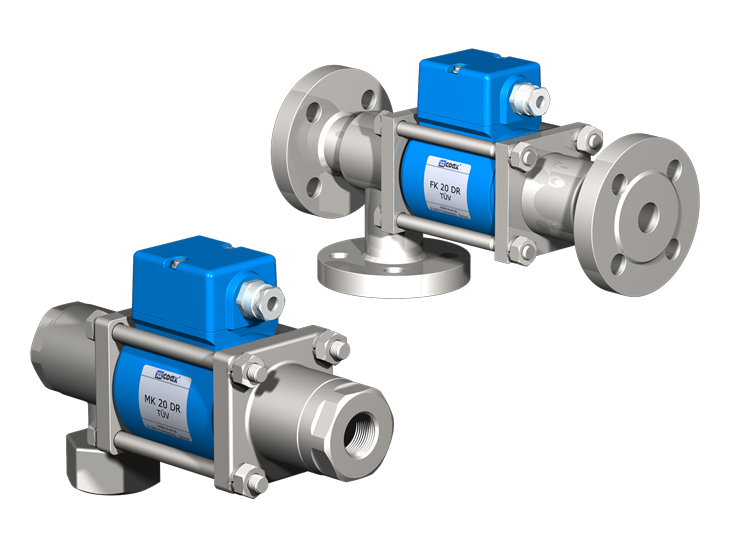

MK / FK 20 TÜV | 20 mm | 7,4 m³/h |

|

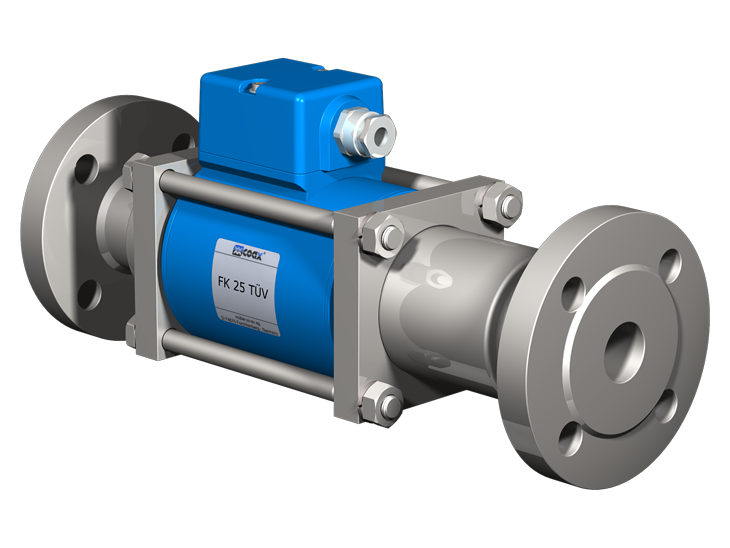

FK 25 TÜV | 25 mm | 11,2 m³/h |

|

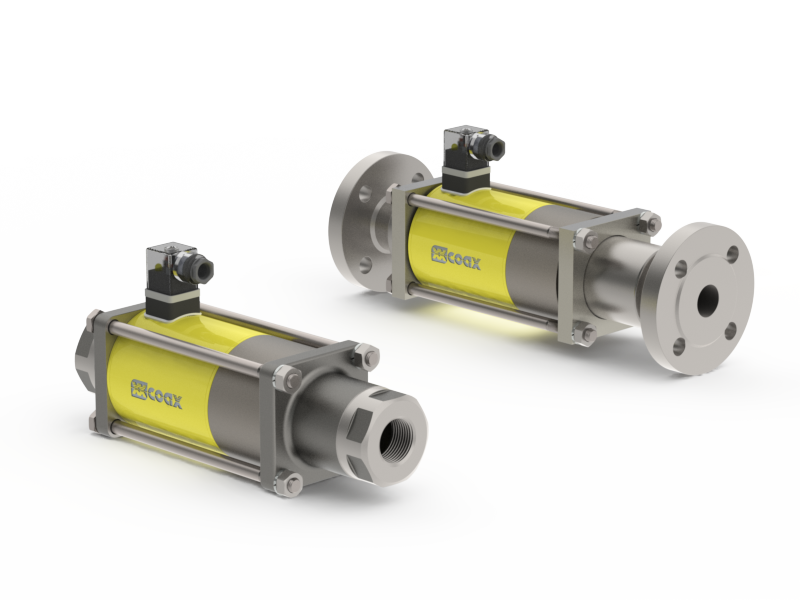

MK / FK 15 DR TÜV | 15 mm | 4,3 m³/h |

|

MK / FK 20 DR TÜV | 20 mm | 6,7 m³/h |

|

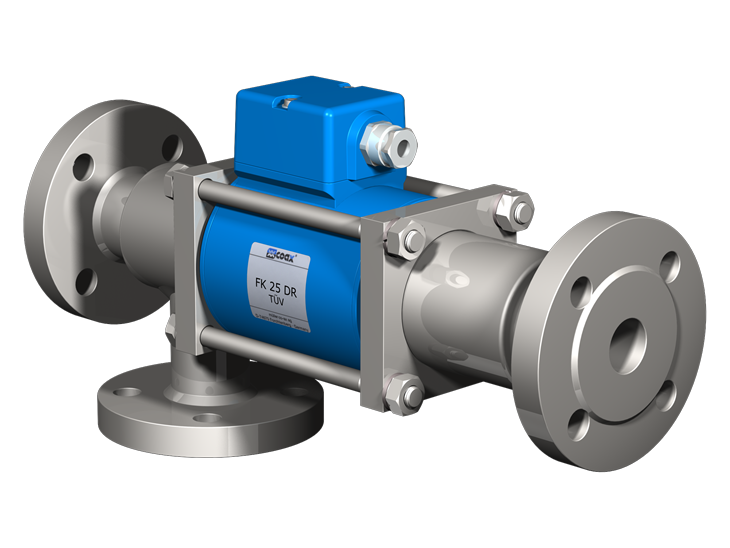

FK 25 DR TÜV | 25 mm | 11,2 m³/h |

|

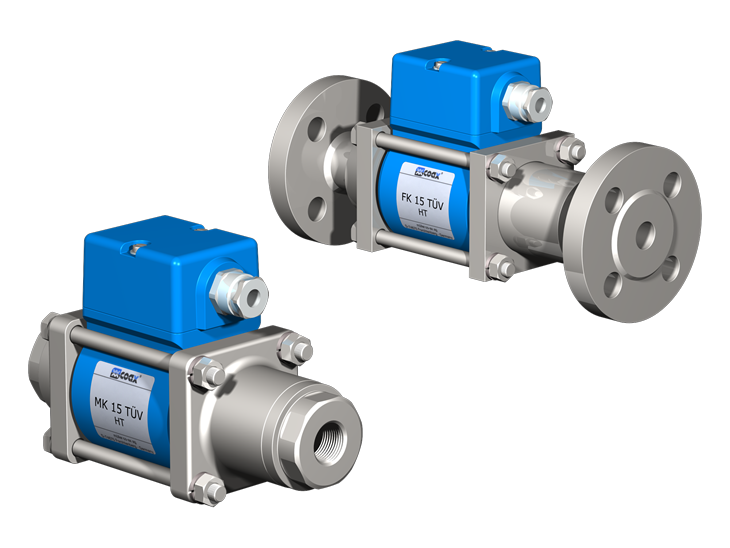

MK / FK 15 TÜV HT | 15 mm | 4,8 m³/h |

|

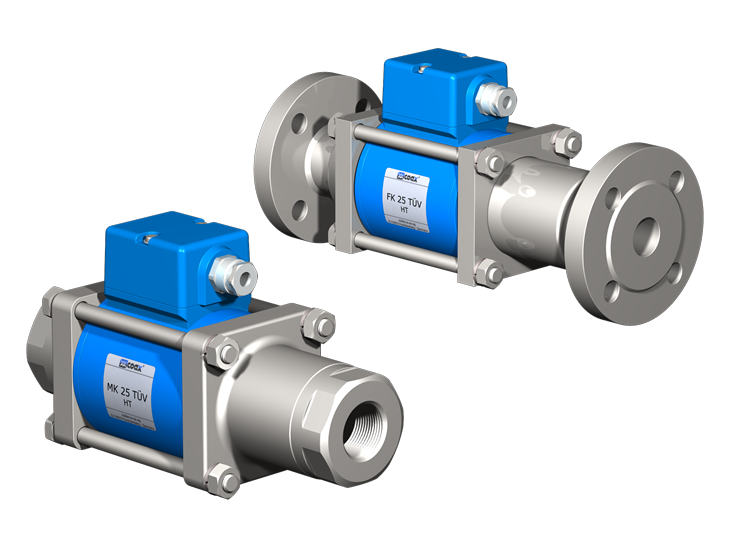

MK / FK 25 TÜV HT | 25 mm | 11,2 m³/h |

The valves’ technical design is based on media and application requirements. This can lead to deviations from the general specifications shown on the data sheet with regards to the design, sealing materials and characteristics.